Why Does Wood Turn Grey? | Prevent or Embrace the Weathered Look

Why does wood turn grey?

The greying of timber, often called “natural weathering,” occurs primarily due to exposure to sunlight and rain. Ultraviolet rays from the sun break down lignin, a component of wood that gives it its natural colour. As the lignin degrades, the wood gradually loses its original hue, taking on a silver-grey patina.

Moisture from rain accelerates this process by washing away the degraded lignin, exposing the underlying cellulose fibres. This photochemical degradation is a natural transformation loved by some for its gracefully aged appearance, though not appreciated by everyone.

Factors contributing to wood greying

While the process may seem straightforward, there are a range of factors contributing to timber weathering. Here’s a deeper dive into the primary players in this natural transformation.

UV exposure

The sun’s UV rays play a critical role in the greying of wood. These rays penetrate the wood’s surface and break down the lignin—the component that imparts colour to the timber. As this lignin degrades, the wood loses its inherent colour, making way for the silver-grey patina. Over time, continuous UV exposure can result in a uniform greying, especially in areas that are directly and consistently exposed to sunlight.

Moisture

While timber has a natural affinity for moisture due to its porous nature, this relationship becomes a bit tumultuous when it comes to greying. Rain, dew, and even high humidity can exacerbate the lignin breakdown process initiated by UV exposure. Moisture not only accelerates lignin degradation but also washes away the broken-down components, exposing the underlying cellulose fibres. This repeated wetting and drying cycle furthers the greying process, especially in climates with frequent rain or varying humidity levels.

Oxidation

Oxygen, an ever-present component in the atmosphere, also plays a part in this narrative. When timber is exposed to air, especially in the presence of sunlight and moisture, the oxidation process is set into motion. This chemical reaction contributes to the changes in wood’s colour, complementing the effects of UV degradation and moisture-induced weathering. Over time, oxidation can give timber a slightly bleached appearance, which further adds to its aged look.

How to prevent wood greying

The only way to prevent natural timber from silvering off is by applying a coating after installation, paired with ongoing maintenance. Find more information on maintaining timber and its colour here.

To minimise the timber going grey, the best methods to employ are the following:

The gradual shift of timber to a silvery-grey hue might not be desired by everyone. For those seeking to preserve wood’s original splendour or slow down its inevitable ageing, several protective measures come to the rescue. Here’s how you can shield timber from the relentless march of time and elements:

- Sealants and finishes: one of the most effective strategies is the application of sealants or finishes. These products form a protective barrier on the wood’s surface, safeguarding it from UV rays and moisture. Clear UV-resistant finishes or sealants are particularly effective as they filter out the harmful ultraviolet radiation, slowing down lignin degradation. Regularly reapplying these finishes ensures continued protection.

- Water-repellent treatments: moisture accelerates wood’s greying process, so reducing its ability to penetrate wood is crucial. Water-repellent treatments make wood more resilient to moisture, preventing the associated degradation and wear. These treatments are especially beneficial in regions prone to frequent rain or high humidity.

- Stains and pigmented finishes: these serve a dual purpose. Not only do they offer a fresh tint or restore the original colour of the wood, but they also provide an added layer of protection against UV rays. The pigments or dyes in these finishes absorb and reflect ultraviolet radiation, safeguarding the lignin beneath.

- Regular maintenance: like any other material, timber benefits from regular care. Cleaning the wood surface periodically with a gentle brush or soft cloth removes dirt, grime, and microbial growth, all of which can contribute to its premature ageing. For decks or outdoor furniture, occasional gentle washing with mild soap can keep the wood looking vibrant.

- Strategic positioning: if possible, position wooden installations or furniture in a way that they’re shielded from direct and prolonged sunlight. Using shades, awnings, or other protective covers can considerably reduce UV exposure.

Embracing the weathered look

SiOO:X is a clear-coat cladding protection and a two-part wood treatment that evolves into a natural grey hue while providing internal protection. Its silicate formula reacts with humidity, dryness, and CO2, gradually enhancing the wood’s color and durability.

The coating penetrates deeply, offering weather resistance and activating upon moisture exposure, making it ideal for exterior timber. Part one penetrates the wood fibers, forming a protective crystal network. Part two is a silicone-based water repellent that bonds with part one, creating a breathable, sealed surface. Maintenance reapplication of part two varies by project.

The benefits of SiOO:X coating

SiOO:X offers deep penetration and accelerated weathering, making it ideal for exterior timber exposed to the elements. It ensures a uniform silver-grey patina across all timber pieces, regardless of species or location, while also protecting against algae, mold, and wood rot for long-term preservation.

A maintenance re-coat is recommended every 5-6 years. However this product can last up to 10-15 years without maintenance.

To speed up the process or cause the timber to weather in non-exposed areas, lightly spray the timber with water once coating has been applied every day for 2-3 weeks. The moisture will react with the coating to ensure an even silvering on the surface.

You need to avoid applying to dressed surfaces as mill glaze resists penetration and can go patchy.

If the surface is scratched or cut, exposing untreated wood, apply two coats of SiOO:X Wood Protection and seal it with SiOO:X Surface Protection. For more information pertaining to different degrees of cleaning, refer to the SiOO:X wood protection care and maintenance guidelines here.

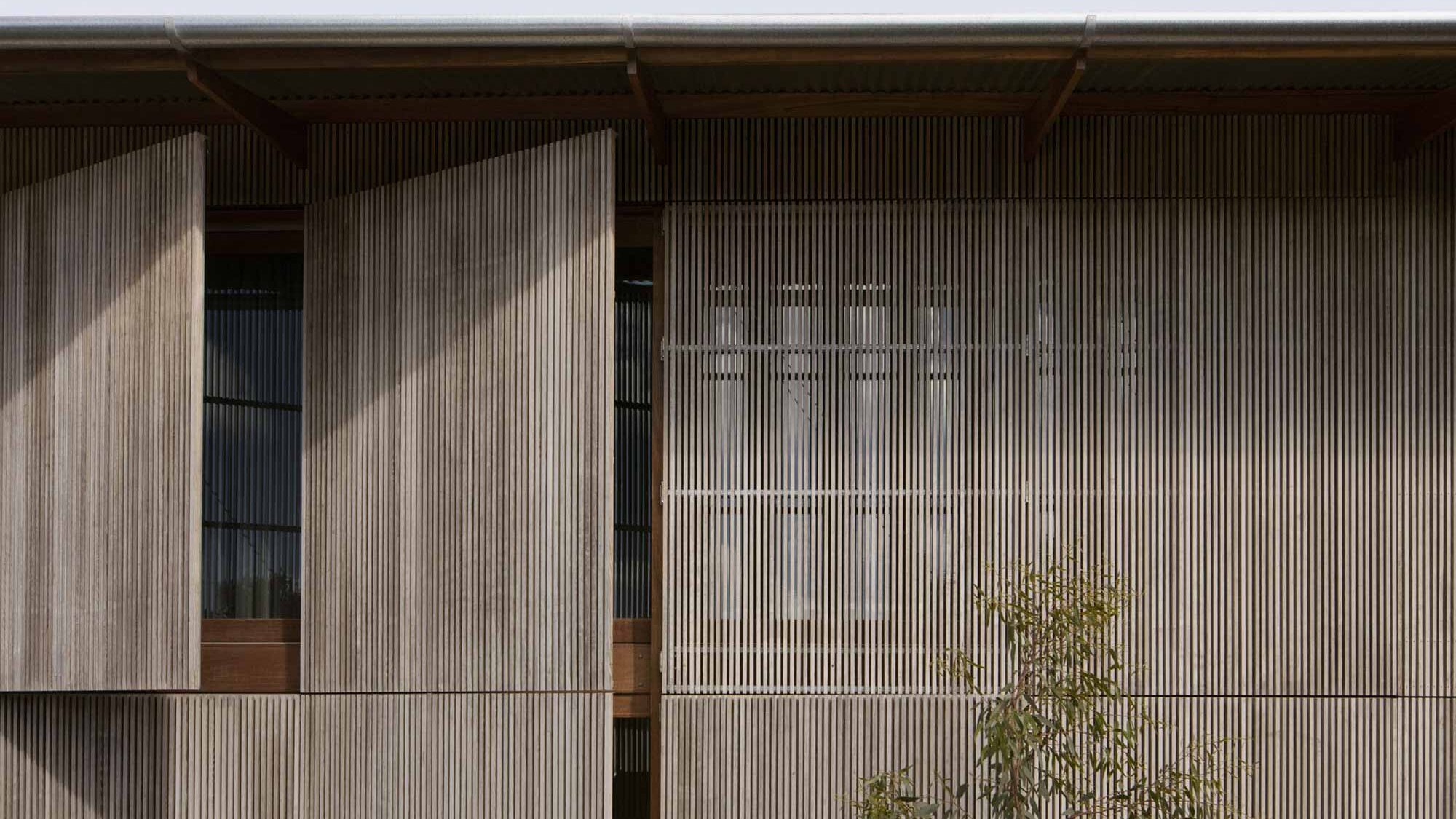

Research Primary School

The architect of this contemporary building at Research Primary School decided to opt for Blackbutt Fine Sawn cladding from our Trendplank range. This type of timber weathers beautifully into a silver grey, offering a sleek contemporary look for years to come. In addition, our Sioo:x protection system ensures the exterior wood weathers without the timber itself breaking down.

Jan Juc Studio

Jan Juc Studio in Victoria is another example of how the weathering process has been used to improve the exterior design of a building. The Burnt Ash battens, combined with a weather protection coating, ensure the timber weathers to a light grey while offering protection to the cladding itself.

Scarborough Beach SLSC

Finally, we have the Scarborough Beach SLSC located in Western Australia. Buildings located near the coast are expected to undergo heavy weathering because they are more exposed to the elements. Instead of fighting this natural process, the architects decided to embrace weathered wood and chose Pacific Teak battens and cladding from our Proplank and Trendplank ranges. The result was a gradual change from the wood’s original colour to a grey timber appearance.

An alternative to SiOO:X

At Mortlock Timber we also offer an alternative to SiOO:X that will instantaneously give an aged and weathered appearance to almost any substrate. This option is a controlled erosion stain that is low VOC, wax and water-based stain that imparts a genuine, weathered look to timber cladding.

This erosion stain has excellent adhesion to natural timber cladding and battens. This type of stain can allow timber products to match new to old, especially on many heritage buildings.

Design with Mortlock Timber

At Mortlock Timber, we supply a variety of external timber cladding options to match both lovers of weathered timber and those who act to prevent it. We work closely with architects and designers to suggest the best timber products to make their projects come to life. From selecting the right timber species to choosing the perfect finish, the team at Mortlock Timber is here to help.

Contact us today for any information regarding our products or for a quotation. One of our friendly staff members will be happy to assist you!

View our pricing and product guide

We are committed to bringing you timber products that add value and endure for years to come, even in heavy traffic and harsh weather conditions. We understand the value of efficiency when it comes to installation and keeping hardwood timber costs down. That’s why we’ve spent decades perfecting our designs to make them easier to handle, less wasteful and more efficient to install. This efficiency allows us to offer you premier products that are more cost-effective so that you can experience greater savings on timber wall costs, timber ceiling costs, timber cladding costs and timber decking costs.

Download our Pricing and Product Guide for our complete hardwood timber price list including timber decking prices, timber wall prices, timber ceiling prices and timber cladding prices.